We are one of the electrotechnical industry key suppliers. We stand out with care for the highest quality of products and customer service. Thanks to the development of competences and a modern machinery park, there are thousands of products in continuous production. Our own, innovative, engineering and technological solutions allow us to ensure the competitiveness of our products as well as quick reaction to market needs. Due to the dynamics of development and market segmentation, we created product divisions: ELECTRO, AERO, ROBOTICS.

ERKO IN NUMBERS

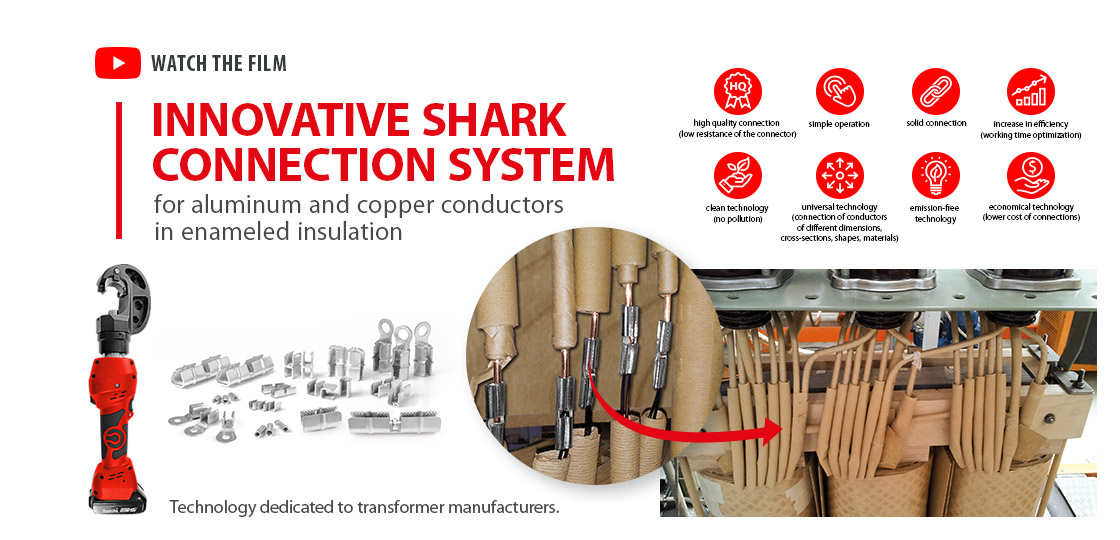

We are a leading manufacturer of various types of cable terminals and connectors as well as tools for electrical work in Poland. Our own design offices, advanced production technology and modern and comprehensive machinery park allow us to quickly respond to individual customer needs.